I founded Lean Coaching in June 2002, to do what it ‘says on the tin’, coach in Lean.

After years of consulting, culminating in 4 years at McKinsey & Co., it was clear to me that what most companies which are engaged in Operations needed, was a sustained improvement process based on the philosophy and principles of the Toyota Production System (TPS), also called Lean.

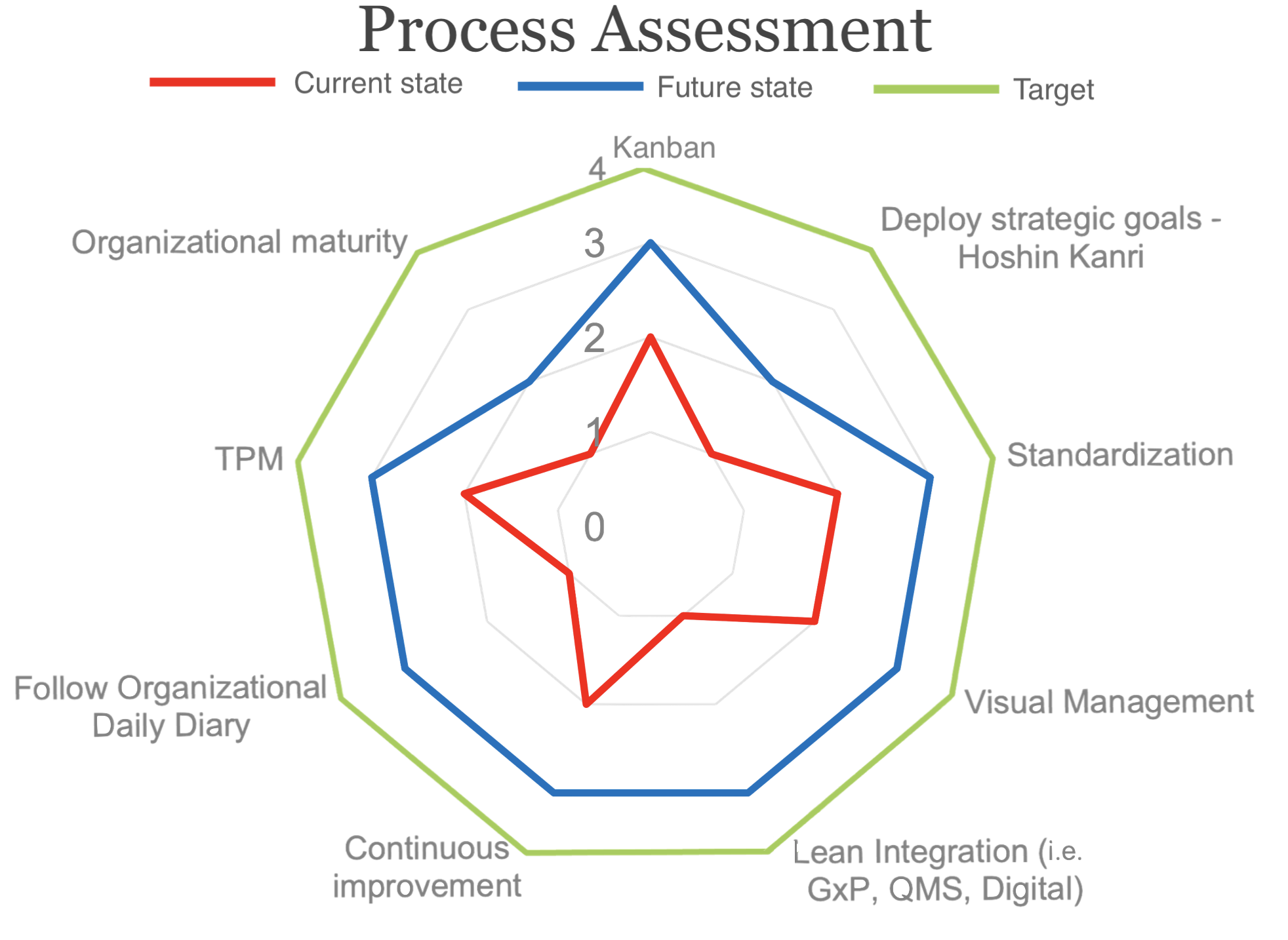

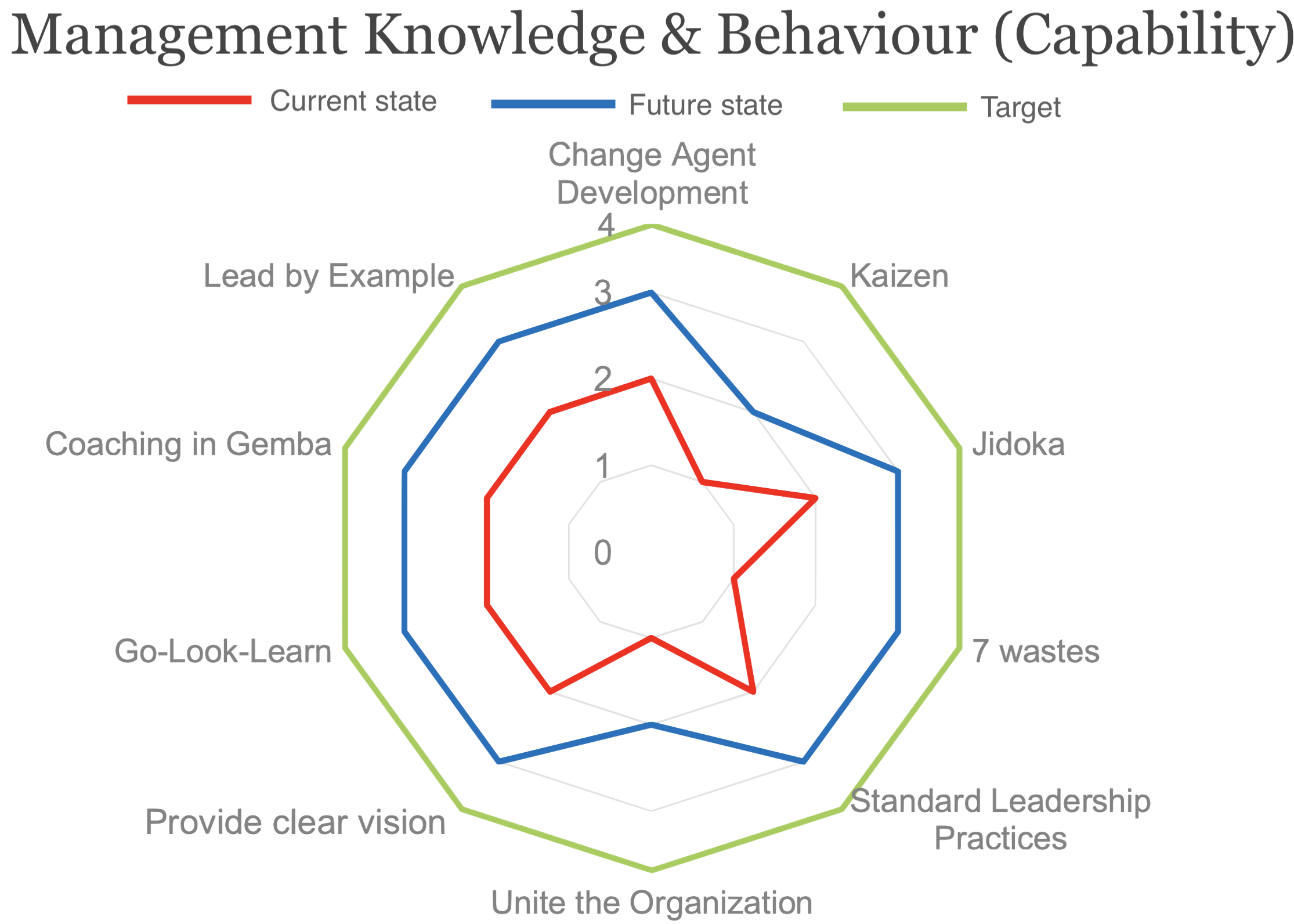

My mentor at the time, Peter Willats, introduced me to the equation: R=PxC, where the Realisable potential equals the (full/financial) Process, times the Capability of the organisation – i.e. even when there is an abundance of potential, the collective capability of the organisation (Management) is usually the limiting factor!

The recognition of this truth, together with the more in-depth acquaintance with the approach used by Toyota when setting up ‘trans-plants’ (copying the mother plants’ systems into new plants), gradually re-focused my attention from the ‘what’ (the tools) to implement, to the ‘how’ (coaching) to implement.

Gert Haar-Jorgensen

Founder and Managing Director of Lean Coaching

Results